Crafts / Carpentry / Table crosscut on table saw - make Mighty miter fence

Warning: although the author uses the facts presented in his own practice and lay out the solutions in the best wish to make the maximal safety of reader, the author does not accept eventual responsibility for injuries that can outcome from the bad reader's judgement, bad or wrong realizations of hereby exposed methods. Even more thou, the exposed methods are only concepts and not the exact blueprints. At the end of the article you can find additional warnings.

Warning: although the author uses the facts presented in his own practice and lay out the solutions in the best wish to make the maximal safety of reader, the author does not accept eventual responsibility for injuries that can outcome from the bad reader's judgement, bad or wrong realizations of hereby exposed methods. Even more thou, the exposed methods are only concepts and not the exact blueprints. At the end of the article you can find additional warnings.

Cutting short laths on a small table saw is achieved simply and with no problems. Of course the miter fence is used for that purposes. But what about crosscutting long board? In that case the tiny factory made miter fence is not appropriate. What is even worse is you risk the strong kickback of fast rotating saw blade.

Sled

Sleds have earlier been in use for crosscutting on small table saws. Sleds were originally intended for cutting small panels or short heavier boards. The emphasis is given here on short work pieces. Simply put, sleds are not intended for cutting long laths or boards which are at larger extent hanging over the edge of table saw.

Particularly dangerous is cutting heavy long boards or panels.

Statistics show that 60,000 injuries are caused by working with table saw with 3,000 of those belong to amputations! Did you know which machine causes the most injuries in woodworker's workshop? Table saw, for sure. Some people thought the sleds can be used for what they are not meant to be: for cutting long and even long and heavy boards. Check out the picture of the operator trying to use his sled for no less then a plank cutting! The problem lies in fact that he has just the tips of his fingers to balance the large part of board hanging over the sled edge!

How should it be done for real

|

The construction of my fence is adopted specifically to the do-it-yourself project and almost every amateur workshop. If you do only woodwork and feel a problem doing metal work - just bring the pictures and your dimensions to a metal workshop and ask them to fabricate the metal parts for you. The parts are easy to make so you will have no problem. Construction of Mighty miter fence is obvious in the following pictures. My solution uses the sliding table part of your table saw, as you can see in the picture; if you have no sliding table on your table saw (rare case), then you can make a sled with added cam clamp. |

Construction

|

The 3 other holes are used to fix the cam lever sleeve, and that will be explained later in text. Of these three holes in one particular moment only one of them is used. The choice of the hole for fastening cam lever will be done on bases of board thickness that is going to be pressed with cam clamp. |

|

Here we have the metal part of my Mighty miter fence. The metal part consists of flat bar slider, L-profile and one metal plate.

On the horizontal part of L-profile you should make 2 threaded holes. In those holes the screws will be inserted; they are used for fixing Mighty miter fence to the sliding table of table saw. (As already pointed out, if your table saw have no sliding table part, you are going to make a sled with cam clamp) |

|

The sleeve consists of three metal plates and the screw which is used to fix the sleeve on the side of wooden part. On the lateral plates of the sleeve there are 2 holes for the cam clamp shaft.

|

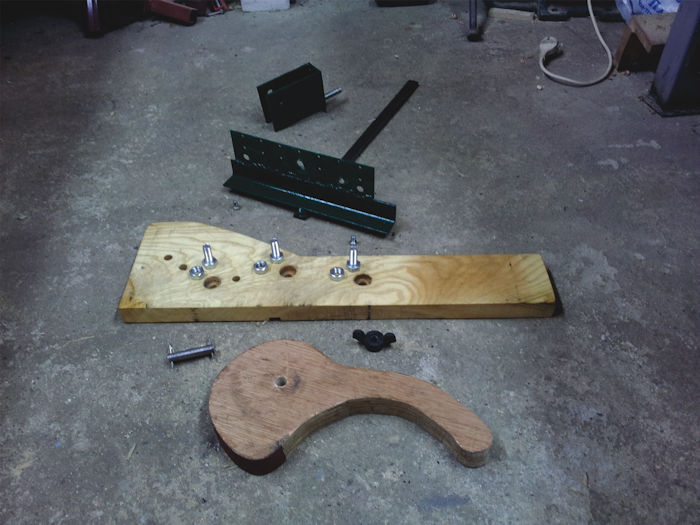

Wooden part is finalized. Above are metal base and the sleeve. |

In the lower part of picture you see the cam clamp. On the lower part of cam clamp we shall glue a send tape for better clamp traction. In the lower part of picture you see the cam clamp. On the lower part of cam clamp we shall glue a send tape for better clamp traction. |

The screws for fixing the wooden part to the metal base, as well as shaft and wing nut for fixing the cam clamp. The screws for fixing the wooden part to the metal base, as well as shaft and wing nut for fixing the cam clamp. |

|

|

Taken for itself, the cam clamp is very reliable. Although this is not the recommended practice in regular operation, here is the picture where I keep my clamp in operation with just one finger, and the other one is used for moving the whole construction with heavy plank that could hardly be held with both hands with ordinary factory miter fence. Compare that to the previous picture with operator using sledge for crosscutting:

|

Conclusion

The suggested making of crosscutting miter fence is incomparably safer solution in relation to the amateur Internet solutions and DIY projects. Here it's all about very economical solution. However readers are warned:

Warning 1: pay attention that common small table saw is generally not safe for crosscutting of long or heavy work pieces. For very long or heavy work pieces I generally recommend additional safety measure by inserting my Universal R1D1 workshop stand under the other hanging part of board. In that way you will get additional safety in specially problematic situations: use both my Mighty miter fence and my Universal R1D1 stand. This still does not mean that your safety is absolute.

Warning 2: using the sliding table part of your table saw is subjected to factory and constructional limitations. That means the sliding table depends on the quality of factory manufacturing and cannot withstand enormous heavy work pieces, so you can expect the crack of parts and possible hurt of operator in those cases, no matter of using the Mighty miter fence or the Universal stand.

To solve this up to now untreated problem I suggest my solution of Mighty miter fence that you can make yourself.

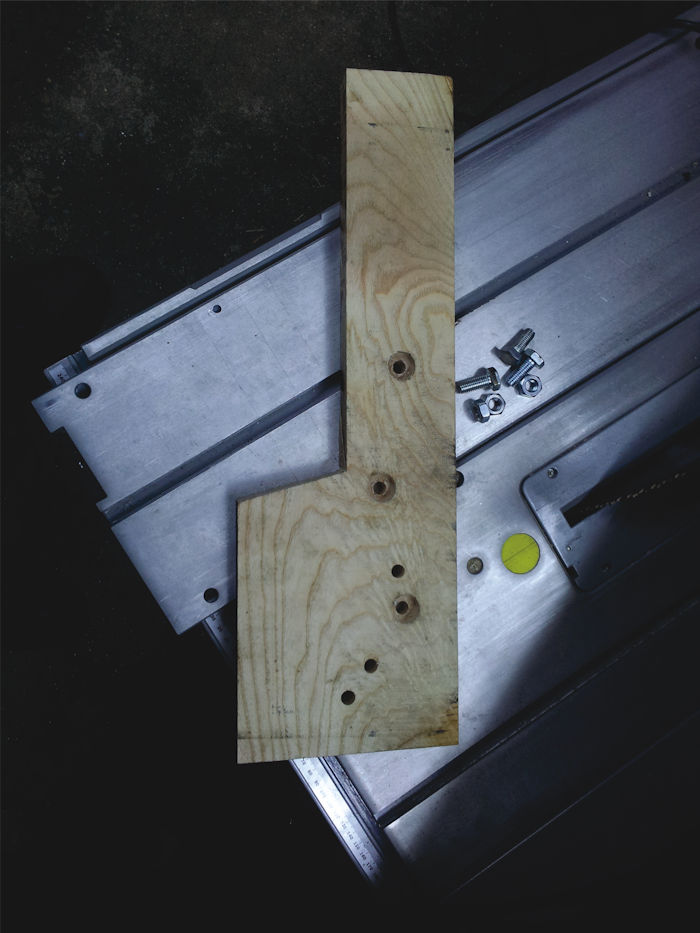

To solve this up to now untreated problem I suggest my solution of Mighty miter fence that you can make yourself. Let us start with rough making of wooden part of Miter fence. You will use hard wood of course. In the picture you see 3 holes with counterboring for nuts. These three holes will be used for screws intended for fixing the wooden part to the metal part of Mighty fence.

Let us start with rough making of wooden part of Miter fence. You will use hard wood of course. In the picture you see 3 holes with counterboring for nuts. These three holes will be used for screws intended for fixing the wooden part to the metal part of Mighty fence. Welding order: slider is welded to the L-profile, and then L-profile is welded to metal plate.

Welding order: slider is welded to the L-profile, and then L-profile is welded to metal plate. Metal part is painted of course. Above the basic metal part there is the sleeve used for

Metal part is painted of course. Above the basic metal part there is the sleeve used for