Agriculture / beekeeping / Bee hive deformation, cause and the solution

Shrinking or swelling of wood because of moisture is sometimes named in carpentry the wood movement. In theory, wood moves in three basic directions: along tangent to the growth rings, radial movement perpendicular to the growth rings i.e. along the line core-bark, and finally longitudinal movement along board fibers i.e. along the length of board. The longitudinal movement is usually neglected. The tangential and radial movement of wood occurs along width and depth of board (respectively or not, depending on the board cut).

Although the bee hive deformation is based on three types of wood swelling, the problem that will be considered in this article has somewhat different explanation that is hidden from practitioners. For that (real) explanation it is not sufficient to study the forestry books. For that I shall offer here what it is actually about in my humble opinion.

What seems to be the problem with bee hives

We meet the problem that bee hive usually cracks at the corners. If you look at the picture on the left, we see the cup deformation which occurs most often at Dadant-Blatt (DB) hives. Let me post a warning here at the very beginning: do not expect the orientation of growth rings always to follow the cup curve as presented, because it can be the opposite then presented!

The essence of such wood movement is two-folded. The first cause of movement is the initial cause of the problem, and the second cause of movement is the wrong practice of bee hive makers, i.e. their ignorance.

The primary cause of wood movement of bee hive is the moisture generated by honeybee society. This moisture causes unilateral swelling of the whole inner side of board.

The other cause of this movement is the beekeeper dilettantism as well as wrong beekeeper's textbooks.

Errors in beekeeper's textbooks

The beekeeper's textbooks have the wrong statement that the interior of bee hive should not be coated. Some authors suggest the bees are coating the hive themselves with propolis and consequently the hive need not to be painted. The truth however is the bees cannot instantly coat the whole hive; they close the holes of couple of millimeters primarily for their protection. If the bees were to use the resources for uneconomical coating of the whole hive they should seize to exist at some time in millions of years of their previous existence during evolution. The uneconomical behavior is immanent to man and not to the bees.

The other opinions cite chemical vapors in paint which are dangerous to bees. This factor can be understood however to be negligible if using the specially formulated paints for bee hives. Also the paint vapors have their natural limit.

Finally there are opinions that bees do not paint their natural brood cavities and still they "operate". This is yet less reasonable statement then before because the natural cavities in live wood with broad opening has no similarity to boards and narrow bee hive entrance. In short the comparison is utterly inadequate.

The mechanism of bee hive deformation

Now I am going to show what is happening in the hive, at least in my opinion. Suppose that for one side of brood super we used a board а by d (w x d) as depicted.

Because of moisture in the hive, one side of that board (the lower on the picture) swelled by a factor к>1. As a consequence, the board gets a cup deformation by the amount of Δ.

We know the dimensions of board. We assume the parameter k as known value and calculate the unknown variable Δ in order to estimate what and how much contribute to the deformation of our hive.

The picture on the right is the college-level trigonometry problem: by using the sinus theorem and solving the system of equations we get the parameter Δ:

\[\Delta = \frac{{2dk}}{{k - 1}}{\sin ^2}\frac{{a(k - 1)}}{{4d}}\]

The meaning of formula

Now let me explain what this result means practically. For DB hive brood super we use the board depth of 310mm and board width of 23mm. Now for swelling from 1% to 8% the formula gives the next result for deformation:

| % | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Δ [mm] | 5 | 11 | 16 | 22 | 27 | 38 | 38 | 44 |

That is, if the bees generate vaporizing and swelling the inner side of board just by 1%, the unglued board would "pop up" 5mm outside the hive measures; for 4% difference and more the hive gets even a hole because the warping of board is larger then the board width itself.

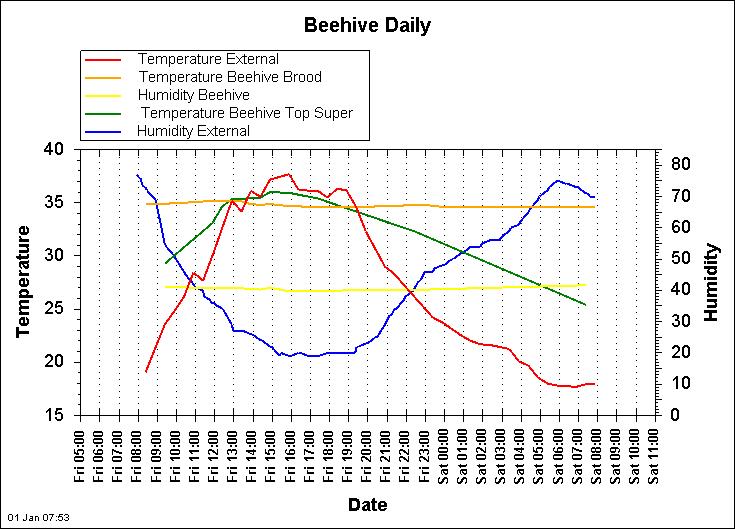

But is it really possible for bees to extend the dimensions of inner board side by vaporizing? To show you the way of solving that question I shall point to the published graph of bee hive moisture measurement (Graeme Lunt from Coburg-а).

Loot at the two lower curves: yellow curve is the relative moisture inside hive, blue curve is outside. The difference in moisture is about 5% during the day.

From forestry tables and the type of wood one can estimate the percentage of wood deformation on the inner side of bee hive. That calculation is out of the scope of this text, because I do not want the reader to screamingly run away from this interesting subject!

Still I shall only say that for soft types of wood usually implemented in Serbia for hives, 25-28% is the typical amount of so called bound moisture (measured in relation to the totally dry wood) that wood can contain; if the board is flatsawn (cut along growth rings) which is quite typical for most implementations, then about 8% of swelling is expected; so for 5% difference in moisture we should have about 5 : 25 * 8 = 1,6% swelling for the real case of measurement.

If we look in the previous table above we find the expected breach of DB hive measures in such circumstances is about 8mm.

Shortly said soft wood used everywhere for bee hive making is almost destined to crack, somewhere later, somewhere as early as in the first year. In some cases even holes at the angles can be obtained.

Another consequences of our formula

If you thought that would be all, as always on my cite - you are wrong! Try to change the board width in the formula. Then you obtain the square law dependence:

\[\Delta \sim {a^2}\]

So, the board width is the most important parameter for "pushing out" the board outside the projected dimensions. We consequently come to idea that the board of a DB brood super pressurize maybe 4 times more the glue joint then the board of DB honey super which is two times narrower! In short, that means further that painting the brood super is obligatory, and of course the choice of good quality "eco" paint. Now you can see the theory is not so boring topic some time?

And how the factor k influences the hive deformation? In that case by checking the formula you get the relation:

\[\Delta \sim k - 1\]

As factor k-1 is in fact the percentage of swelling of inner board, we conclude that "popping up" of board is directly proportional to this value. E.g. double percentage swelling of inner board means double popup of board outside the hive.

Final conclusion

My statement is every bee hive super with height over 200mm should obligatory be painted inside with ecological paint for lowering the effects of hive deformations. Your experience, in respect to the moisture of your terrain where your hive are positioned, as well as specificity of bee hive construction (type of wood, joint types, quality) could lead to some other board height as relevant for painting inside. In the case of DB hives, definitely, the brood super should always be painted, and the honey supers according depends on your choice and economy.