Crafts / Metalworking / Making pipe clamps

Let us see first what opportunities do we have when deciding to buy or make a pipe clamp. We have the option of buying factory made one, or wood or metal DIY (do-it-yourself) clamps.

Factory made variant of pipe clamps

|

|

|

Pipe clamps are available in the factory or DIY varieties. On pictures one can see the look of factory variants. What are the flaws of these models? Firstly they are expensive; secondly they are not readily available in lots of countries, and thirdly there are existing far cheaper and more attainable DIY variants. Conclusion that comes out about factory variants that should be used is clear by itself. From aforementioned reasons a lot of people resort to wooden clamps variations of pipe clamps, with more or less implementation of metal parts in them. |

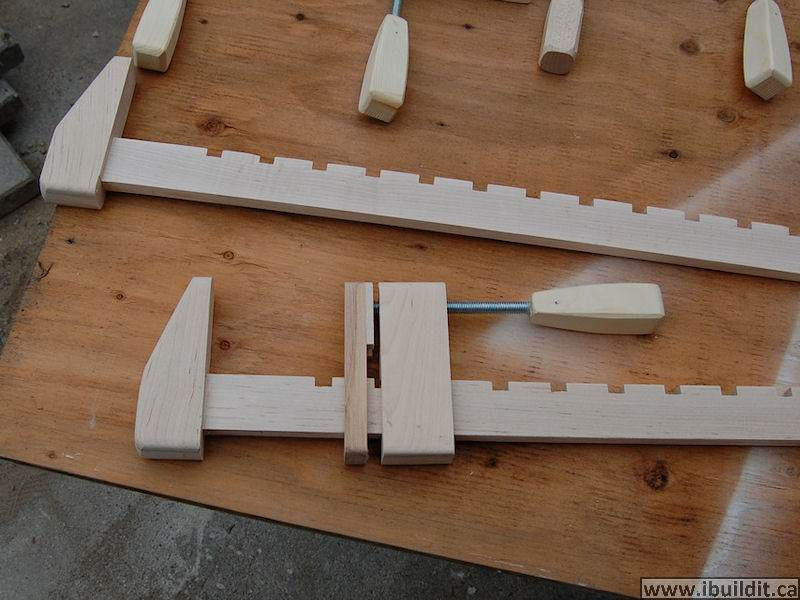

Wooden clamps imitating the pipe clamps

|

|

|

Wooden clamps are made as combination of wood and metal, and wood having the predominant role. Wooden clamps are weaker by construction as much as wood material exists in the construction. Secondly some realizations of those clamps are somewhat time consuming. Models having wood as shaft material have no extension possibilities. Also wooden clamps are often considerably larger then metal ones. |

Common flaw of existing solutions of pipe clamps

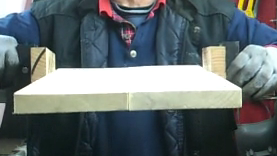

All previously quoted solutions have also one important restriction. Namely those solutions impose vertically distributed pressure to the work piece, which is sometimes desirable and sometimes not. Take a look at the picture above this paragraph and observe the edge joint (horizontal lamination): two horizontal boards endure vertical pressure, which is not appropriate. Better implementation would be if these horizontal boards are subjected to horizontally distributed pressure.

Proposing solution: my realization of universal pipe clamp for carpentry and metalwork

|

The advantage of such horizontally distributed pressure is the saving of the number of used clamps in some jobs, especially in carpentry. Additionally horizontal lamination would have stronger joint because of pressure imposed in horizontal direction. |

Clamp construction

Clamp consists of three parts: handle part, two clamping jaws and central bearing tube. Their look and fabrication I shall explain in the following text.

|

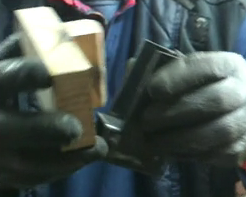

In the left part of the picture there are the jaw parts: a slider and three flat pieces above it. These three flat bars should be welded to the slider and forming a slot so it can accommodate a wooden block. A slider is a 30mm square tubing.

|

|

Completed jaw is also presented in the picture. Make a note that during fabrication you should insure the vertical edges of flat bars to be truly vertical at the outside, because the wooden block is aligned to those edges. Now here is the catch: you can use the jaw either with wooden block inserted in the slot, or you can turn the jaw and use it with no wooden block. |

|

You can see the equidistant holes on central bearing profile that is used to accept nails which fix the slider in specific position on bearing profile. |

|

|

|

The short extension profile has also two pairs of holes at both ends. These holes are aligned with end holes on bearing profiles and a nail is inserted through holes to achieve the extension. |

The handle part consists of a handle, threaded bar, two nuts and two square tubes 25mm and 30mm. The lower square tube is a slider; it contains a pair of holes used to receive nail that fixes the handle part on bearing tube. The handle part consists of a handle, threaded bar, two nuts and two square tubes 25mm and 30mm. The lower square tube is a slider; it contains a pair of holes used to receive nail that fixes the handle part on bearing tube. |

In the picture you have the basic clamp set for horizontal lamination. In the picture you have the basic clamp set for horizontal lamination. |

Unique quality

Now let me summarize the advantages of my clamp over inferior DIY solutions or factory made.

|

Simulating carpentry mode of work on factory made pipe clamps (classical design) by using additional pieces of wood is not the replacement for my proposed clamp. Namely inserting wooden blocks does not give precise, parallel and firm support. On the contrary to that simulation, the adopted wooden blocks in my construction goes deeply into the jaw slot in my clamp and give balanced pressure to the work piece. Carpentry mode of work provide for clean work without scars on soft wood, that would be the opposite in the case of metal work (see the text below). In the case of work with larger number of clamps, this mode of operation will potentially lower the number of clamps needed. |

|

|

|

Clamp is also very suitable for small workshops because of compactness. By construction all crucial parts are made of steel and from pieces readily available for DIY work. Clamp has firm construction and can be extended to form clamp of arbitrary length. |

Now take a look at my construction of pipe clamp in the picture on the left. Firstly, all elements are made of steel with the only exception of wooden block and wooden handle, which should be acceptable from the point of comfort, strength and functionality. The clamp is distributing the pressure to wooden block in the horizontal direction. This horizontal pressure is specially suitable for most carpentry projects, and predominantly for the horizontal board lamination as can be observed in the picture on the right.

Now take a look at my construction of pipe clamp in the picture on the left. Firstly, all elements are made of steel with the only exception of wooden block and wooden handle, which should be acceptable from the point of comfort, strength and functionality. The clamp is distributing the pressure to wooden block in the horizontal direction. This horizontal pressure is specially suitable for most carpentry projects, and predominantly for the horizontal board lamination as can be observed in the picture on the right. Here one can see the basic jaw parts. There are two clamping jaws. In the right hand part of the picture is the metal part of one jaw.

Here one can see the basic jaw parts. There are two clamping jaws. In the right hand part of the picture is the metal part of one jaw.

In the lateral flat profiles we shall drill a hole and make a thread in it for a screw. The screw purpose is to fix the wooden block in place so it cannot move during clamp manipulation.

In the lateral flat profiles we shall drill a hole and make a thread in it for a screw. The screw purpose is to fix the wooden block in place so it cannot move during clamp manipulation.

Wooden block consists of two parts glued together. The smaller part goes into jaw slot. After that the wooden block is fixed in place with screw by means of hand or wrench.

Wooden block consists of two parts glued together. The smaller part goes into jaw slot. After that the wooden block is fixed in place with screw by means of hand or wrench. The central bearing profile is 25mm square tube. In the picture you can see extension by means of two bearing profiles and the short extension (30mm square profile).

The central bearing profile is 25mm square tube. In the picture you can see extension by means of two bearing profiles and the short extension (30mm square profile). Carpentry work: turn the jaws for horizontal pressure distribution. This is probably unique solution.

Carpentry work: turn the jaws for horizontal pressure distribution. This is probably unique solution. Metal work: by turning the jaws on my clamp 180°, the clamp gets ready for the classical work like classical pipe clamps. This mode of operation can be called "metal mode of operation". In the picture you can see that.

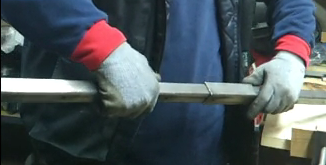

Metal work: by turning the jaws on my clamp 180°, the clamp gets ready for the classical work like classical pipe clamps. This mode of operation can be called "metal mode of operation". In the picture you can see that.