Crafts / Carpentry / Concealed Hinges, Calculation and Special Considerations

On the Internet and in books I observed a number of articles about concealed hinges (Euro hinge, cup hinge). Seemingly they all have the same characteristic: they approach to concealed hinges topic as light and incidental. The concealed hinges implementation is sometimes easy but quite often it is not.

In this text I shall approach to concealed hinges topic in proper manner that will enable reader to implement very precisely the concealed hinge in cases where even professionals could have a problem. From my notebook I am bringing you my own sketches how I calculate concealed hinges myself in my own practice. Up to now, all this data and the calculation details have not been presented in any carpentry manual or anywhere on Internet or in any media. You will conclude for yourself if my approach is useful or not.

First things first: terminology

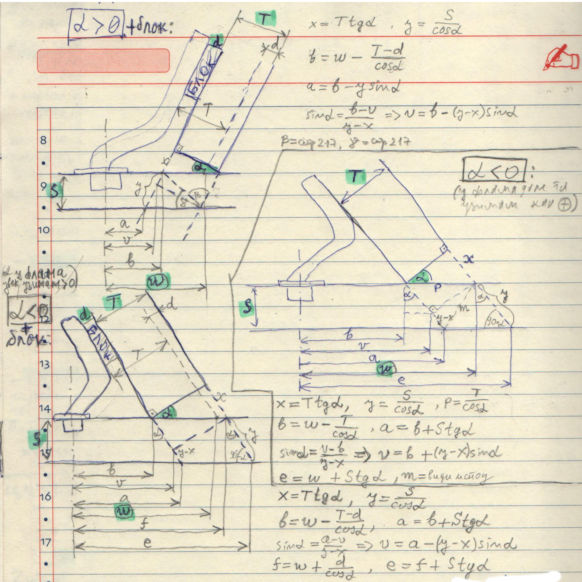

Concealed hinges are used for mounting door on the side of carcass of kitchen element or wardrobe, for example. For the purpose of this text we shall use the names (see picture on the left): плочица=mounting plate, рука=arm, колено=knee, чашица или шоља = cup and и носач чашице = cup rim.

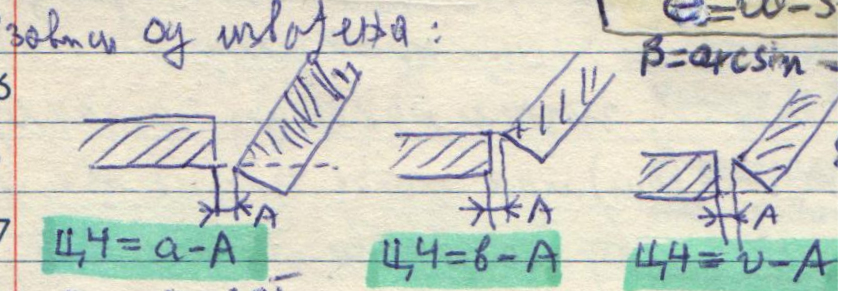

For the sake of completeness let me mention - there are three types of concealed hinge: straight-arm hinges, half-crancked hinges and full-crancked hinge (see picture on the left fot this last one). Normally the streight-arm hinge is used for mounting a door that will maximally overlap the edge of a carcass side (overlay door) and the full-cranced hinge is for mounting a door fully inset into the cabinet (inset door). Half-cranced hinge is principally for mounting a door partially overlapping the edge of carcass (partial overlay door), tipically when two doors meet on the same vertical edge of carcass.

|

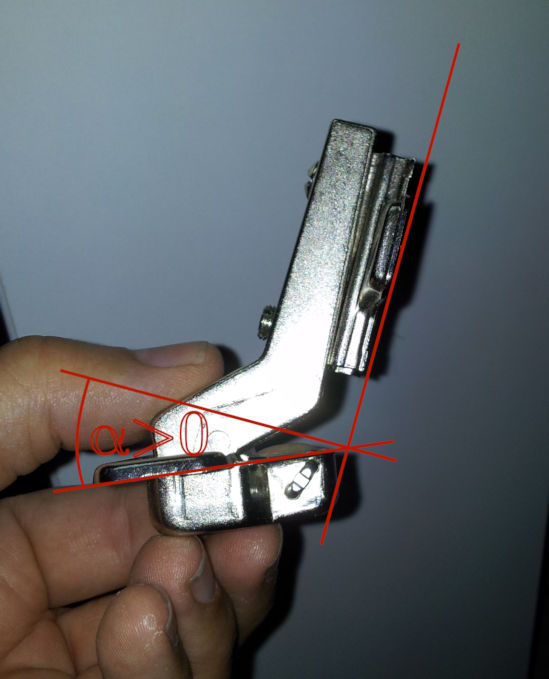

We define here the angle α of angled hinge as positive or negative angle that would be needed to rotating the cup of concealed hinge to assume perpendicular position to the mounting plate, when hinge is in closed position. In the picture I marked the angle α and in this case it has the positive angle value. The hinge manufacturers are always underline some other angle and that is not the angle α but the opening angle. The opening angle is the maximum angle of opening a door operated by that hinge. What seems to be the problem anyway? |

|

|

Take a look at my kitchen element on the left. The right side of carcass (your right side) is angled in order to blend practically into the corner. The left side of carcass is standard 90° side. The demands for concealed hinge on the left door: opening angle should be 90°, we need inset door mount, consequently we use full-cranked hinge type. Those hinges are standard and you can always find them on the market. But what hinge do we need for the right door? The demands for right hinge are as follows: opening angle should be very wide, say 120°-130°, we want inset door and consequently there will be full-cranked hinge. But where are we going to find it? Suppose you have an angled concealed hinge as presented in my hand in the picture on the right and suppose it has the wanted opening angle for the right door of my kitchen element. Make a notice of red line marking the line of mounting plate base which corresponds to the inner side of carcass. It is clear from the picture that the hinge alone cannot be used for inset door because the side of carcass would collide not only to the door but also to the cup of concealed hinge itself. The hinge alone is applicable only for overlay doors only, and we need the inset door! |

|

Larger manufacturers print catalogs of concealed hinges with some discrete angle α values for angled carcass sides. Those hinges are expensive and not always at your disposal in many countries. But what if your case asks for specific angle α not covered by catalog options, as is our example above? In that case manufacturer expects from you to maximally stretch the range of hinge adjustment possibility; however this adaptation is normally used for precise adjustment of cabinet door and not the compensation for side angle difference. If used for angle adjustment, we often cannot adjust the door afterwords. And not even mentioning that every deviation from catalog means lost of time and uncertainty in process. The solution should be a quest for angled streight arm hing, but what if we have some special angle we want to realize? The special hinges have also considerably higher price as well. What are we to do if we have not such special concealed hinge?

|

|

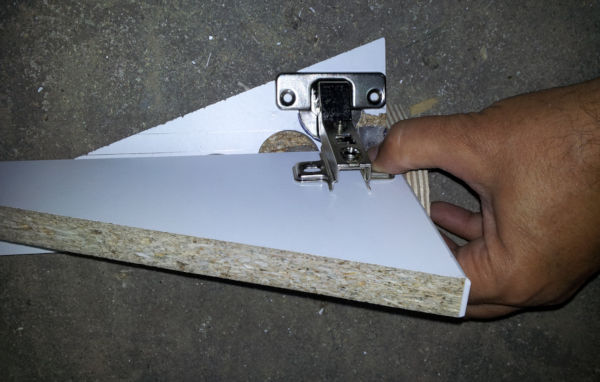

My solution would be to implement additional (wooden) block to enlarge the hight of standard hinge mounting plate. How this looks you can in the following pictures:

|

|

So the right door uses our angled concealed hinge with wide opening angle, and inset feature is achieved by mounting the hinge plate on wooden block of plywood of exact height level. The left door uses the standard concealed hinge |

|

The right door uses our angled concealed hinge with wide opeining |

This is all very fine, but how are you simply discover the thickness of wooden block needed to mount the concealed hinge of carcass right side?

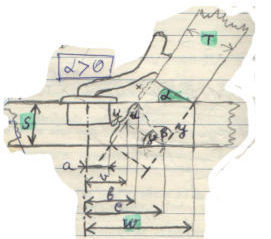

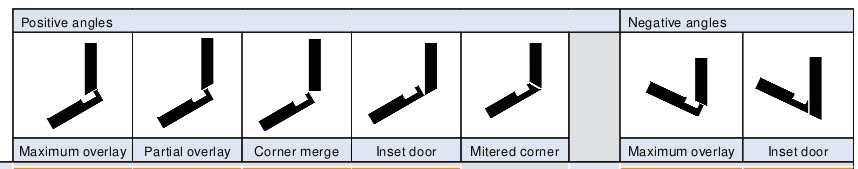

My formulas for concealed hinges with positive angle α >0, with no block

First I present the simple hinge installation that does not use any additional wooden block:

|

|

|

|

|

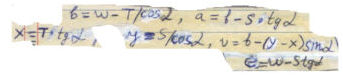

Formulas for angle α >0: make a notice of green marked variables. They are the main input parameters that you will use in my formulas. More about it in following text. |

In this and all other formulas presented in the article, the angle α is used with absolute value (positive), although in the text here we speak about angle α having positive or negative values depending on construction. |

Make a note that in the picture for angle α >0 the variables S, T, w, angle α are basic variables needed for formulas implementation. Also note that for our example project of kitchen cabinet we shall cut the right carcass side will be cut under the angle 90-α. From all variables in formulas you will know all parameters but one: w. This is the distance of cup center to the nearest edge of door in the inset door case.

Parameter w

My w parameter is obtained in a very simple way: we use the simple template for measuring the w parameter of any existing concealed hinge.

|

Template is made of available scrap wood, here MFC melamine faced chipboard. There are three holes of which the upper one is the only one functional. The two surplus holes are traces of my experimenting :-) Above the upper hole you see the plywood fence screwed to the MFC; below fence is the part of old metal measuring tape which usage will be clear soon enough. In the upper hole we shall insert the cup of our concealed hinge whose parameter w we intend to measure. |

Concealed hinge must be adjusted before our measurement, either by screws to have exactly the angle α as it would have when mounted on our kitchen element with doors closed. For example, if the angle α=110° we shall adjust the hinge with screws so our hinge has exactly that angle, as I am presenting in the picture below. Alternatively this angle α will be adjusted by inserting a washers on the bottom of upper hole below the cup as shown in the picture on the left.

|

In this picture down there I am presenting checking of angle α=90°, of standard hinge used for the left door. |

When we prepared the concealed hinge as I explained, here is how the measurement of w parameter is done:

|

|

|

In my hand I keep the scrap part of door MFC, with one side stuck to the fence, and with the other side pinched to the concealed hinge. On metal tape we read parameter w.

Distance of hinge cup to the edge of door

The position of hinge cup on the door depends on two parameters: parameter K and parameter A. The range of these parameters depend on construction of concealed hinges, i.e. they are different for various manufacturers. K parameter is in range usually from 3 to 6mm, and some manufacturers even 7mm; it stands for distance between the edge of cup to the edge of door. Parameter A can be understood from previous sketches of mine (see picture) for the case of inset door; for overlay door parameter A is the distance from the door edge to the outer side of carcass. In most cases we shall not make mistake if choosing parameter A in range 0,5-2мм.

What do we need A and K parameters for? By choosing them we shall get one additional equation to obtain parameter a (lower case a, different from A) in formulas. Namely on the bases of previous discussion, parameter а=A+K+Φ/2, where Φ is cup diameter, in our case 35mm.

Parameters A and K we choose on our will: it is paramount only they are in allowable range of values. Now for the parameter a we actually have two formulas existing simultaneously - one is quoted in this parameter, the other is from the previously quoted formulas.

What do we need formulas for?

The whole point is that without formulas we could not have the computational way to find the thickness of wooden block, to start with. Or we could not know how to measure the width of outer side of carcass if that side is angled. To understand my point look at the next picture presenting some variants of carcass-door mounting. Which of the small pictures correspond to our example of right door?

That is the fourth picture of course, presenting the inset door with angled edge of right carcass side. There is a question: what is the outer width of right side of carcass of my kitchen cabinet? If looking my previous sketch for α > 0 you can see that in our example we have the carcass side elongated on one side by Y, and on the other side it is longer X+Y in respectfully to the measurement template we used when determining the w parameter. The circular saw angle when cutting the edge of carcass right side will be 90°+α. However you have all the parameters S, T, w, а, angle α, so by making use of my formulas you can easily and precisely calculate the value of everything you need to make the proper construction and cutting of sides of carcass and doors.

па помоћу мојих формула лако налазите прецизну величину било чега што вам треба да правилно извршите сечење стране корпуса и крила.

How shall we determine the thickness of wooden block needed in our example?

The previous formulas I presented has prepared you to work in cases when wooden block is not needed. But in the next pictures you will find the rest of my notebook formulas for all the other cases: the first depicted is the case of positive angle α>0 with блок (block; yes this is good time for you to learn Serbian, why not). Then follows the cases of negative angle α with block and without block.

Let's go back to our case - i.e. the case of right inset door with positive angle α and additional block. That is the first part of sketch above with boxed "α > 0 плус блок". How are you going finally to get the thickness of wooden block?

As told before you have on your disposal the parameters S, T, w, а, α. By using the first equation you will solve x, with other equation you solve y, from the forth equation you find out b and finally from the third equation you will calculate d which is the block thickness.

Conclusion

You can rely on manufacturers catalogs only for some discrete values of hinge angles quite limited in number. If anything in your cabinet construction differs from official catalogs you have to find your own way how to do it. In this text, for the first time ever, you have my public presentation of my universal method how to use available concealed hinge for your specific carpentry project.

13.2.2016

easy